Say Hello to Stress-free Machining Operations

We have developed a Five-Phase Preventive Maintenance Program to give you peace of mind even when you aren’t at work. The first two phases of this program provide you peace of mind. In the first phases, we leverage J&L, Renishaw, FARO, Hamar &/or other metrology solutions to analyze your most critical machines, so we can predict & minimize scrap, outages & emergencies.

Phase 1: Critical Machine Analysis

- Assess the health of machines most critical to production.

- Recover accuracy & reduce scrap with adjustments.

- Reduce downtime risks, emergencies & team stress.

Phase 2: Scheduled Maintenance

- Increase productivity, quality, and repeatability.

- Minimize scrap, crashes & downtime emergencies.

- Reduce repair costs & allow budgeting, no surprises.

- Maintain asset value over extended machine life.

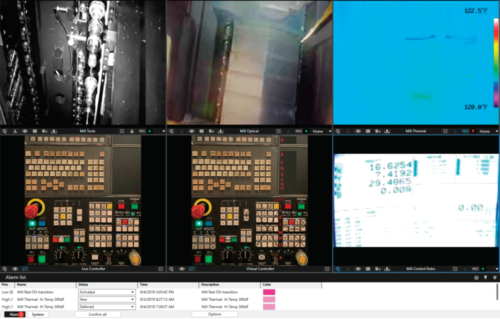

Phase 3: Monitoring

- By watching machines continuously, we can save your team time by detecting issues that can be safety hazards or lead to machine failure.

Phase 4: Remote Control

- Run long machine cycles overnights, weekends, and holidays.

- Automatically address common issues saving your team time.

- Restore production without the need to physically visit the plant on off-hours.

- Leverage remote support and outsource some team functions.

Phase 5: Automation

- to help your team find their higher purpose. By using cobots for mindless repetitive tasks (i.e., Machine loading & unloading, Assembly, QA, etc.) we are able to free up your team to focus on creative and production-maximizing activities.

Resulting in:

- Cost Savings from reducing major equipment failures.

- Improved Safety by reducing occurrences of employee injury.

- Improved Reliability by increasing productivity, quality, and repeatability.

- Conservation of Assets – maintain asset value over the intended lifespan of the machine.

With the peace of mind that MPE has provided for your machining operations, you will be able to expand machining capacity without the need to hiring additional machine operators, techs, and engineers.